ZHENG CHANG new generation

Reliable Pig Feed Hammer Mill

Use the latest multiple impact shear structures

Crushing efficiency is higher and more stable

Crushing is one of the important processes in pig feed processing. The crushing will not only affect the efficiency and quality of the following processes, such as mixing, pelleting, extruding and expanding, but also affect the feed cost, nutritional value, sow performance, animal healthy and environmental health.

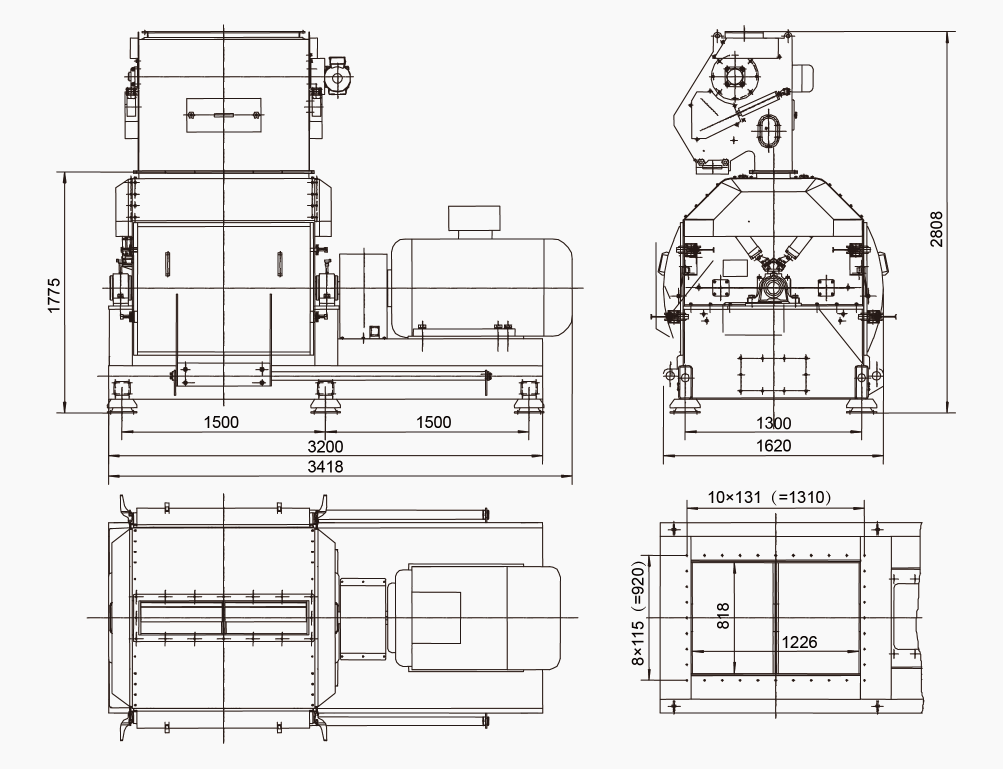

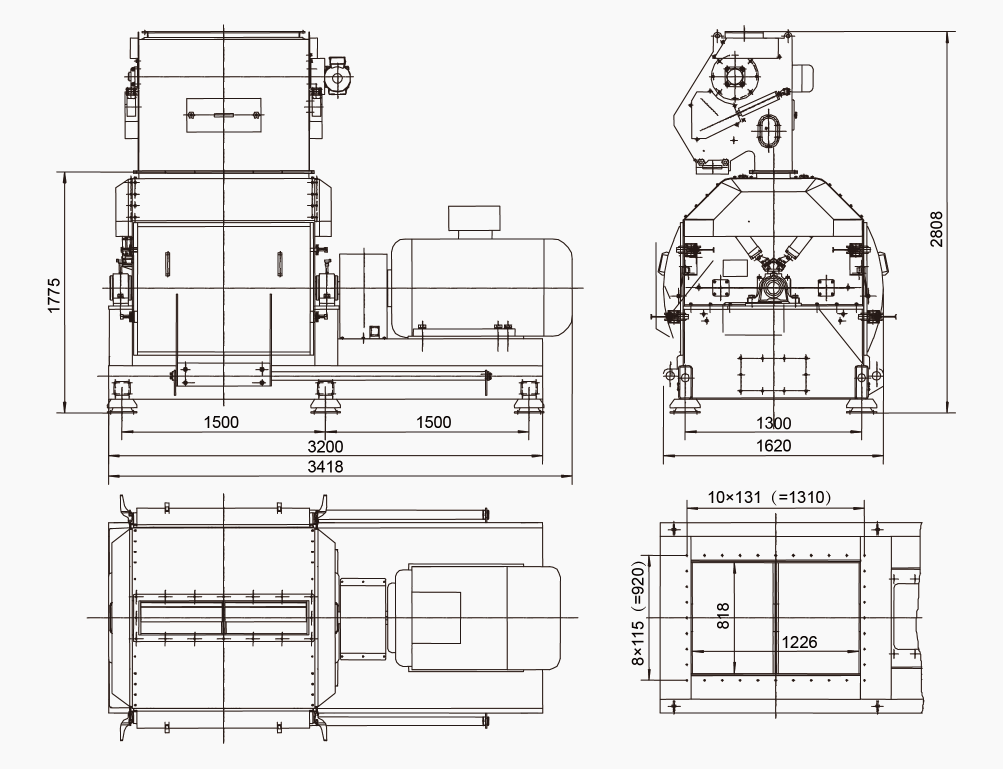

Therefore, a large number of pig feed enterprises put forward higher requirements for the key performance indicators of hammer mill, paying more attention to its crushing efficiency, crushing effect and stability. ZhengChang launched a new series of reliable hammer mills, including 4 models like SFSP120x50A、SFSP120x70A、SFSP120x 80A、SFSP120x110A, which will bring more choices to customers and enhance the economic and breeding benefits of enterprises.

The advantages:

(1) ZhengChang latest multiple impact shear structures have greater shear effect and higher crushing efficiency and stability.

(2) Optimum design of equipment core assembly, high speed operation, higher output, more stable and reliable.

(3) Multi-crushing cavity combination patented structure, more uniform abrasion, lower noise, low cost and longer service life.

(4) Simple and fast installation, maintenance and replacement of hammer.

(5) The application of high-quality sensors ensures that the operation control of the equipment at any time, which is safer and has more accurate control of finished products.

More optimization:

(1) More choices

This series of hammer mills has a variety of sieve aperture options (0.6, 0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 4.0), which can realize the coarse crushing and fine crushing.

(2) More Innovation

The structure has been re-improved and innovated, adding adjustable crushing zone. Under the combination control of cylinders, adjust the crushing zone to change the wind field of the crushing cavity, greatly improving the impact frequency of materials.

The multi-cavity patented technology makes the material distribution uniform and effectively reduces the circulation phenomenon in the crushing process. The crushing particle size is more uniform. Under same sieve aperture, the crushing particle size of the hammer mill is increased by more than 10%. Compared with the same type in the market, the crushing efficiency is higher and the output is larger. For example, when the corn with moisture less than 13% is crushed, the output of SFSP120x100A can reach 33-50t with 2mm sieve. It ensures the stable and efficient production of pig feed enterprises, and is conducive to the sustainable development.

(3) Lower noise

The optimum design of heavy base and the usage of bell shock absorber can effectively reduce vibration and noise, so that the noise can be controlled below 95 decibels.

(4) Intelligent and safer

A. Equipped with multiple cylinders, the automatic control of various plates can be realized.

B. Equipped with vibration sensor and bearing temperature measuring device, the operation of the equipment can be mastered at any time, which is safer and the control of finished products is more accurate.

C. Equipped with Honeywell mechanical safety protection switch and electromagnetic safety lock to prevent the opening of the operation door in the production process and ensure the safety and reliability of the production process.