A Harvest Production Line for Happiness

✦Give employees a stable, reliable and lasting income Zhengchang production line.

✦Give shareholders a triumphant, quiet and rich space.

✦Send to distributors and breeders suitable for stable and rich high quality feed.

✦Give operators to create benefits, enhance value, realize the dream of the spiritual home.

✦Give the enterprise a beautiful factory that is environmentally friendly, clean and creates wealth.

✦Give them Zhengchang high-efficiency equipment comparable to European and American grades.

✦Give each of them a profit space with their own unique environment.

✦A better way to please your family than 5 million cash-is to send them a harvest production line that can create a big future together!

Whole Process Customized Engineering Solution System

Zhengchang grain machine is a feed machinery industry as the main body of the feeding section machinery processing equipment and the whole plant engineering manufacturing enterprises. The company has established the goal of medium and long-term war road, standardized management of product design and development, procurement, manufacturing, sales and service process, so as to ensure that the whole product realization process is fully guaranteed, and the whole process forms a complete value chain. Each activity is a value-added process, creating value for customers, employees, suppliers and society.

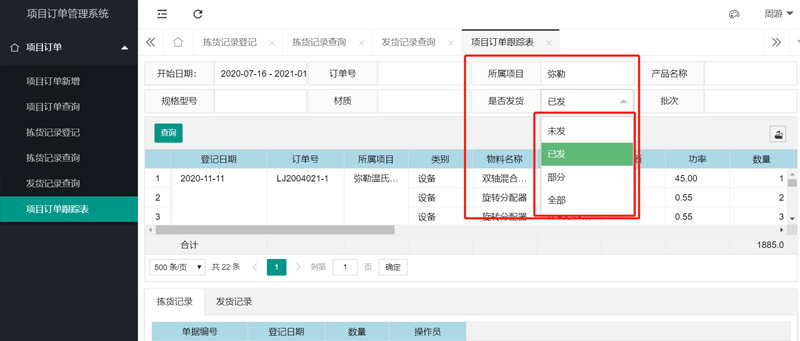

From order requirements-technical design-planning-scheduling-material procurement-production execution-warehouse management-sales, shipment-commissioning and acceptance-after-sales service, the whole business flow management and control are realized, delivery tasks are completed on time, cost reduction and efficiency increase are realized, and customer satisfaction is improved.

Opening a Green Channel for Fast Delivery

In the face of projects with a short period of time, Zhengchang specially opens a green channel for you to shorten the installation period, I .e. to make various preparations before placing an order, such as detailed planning, project construction plan, all delivery batches, detailed completion of materials to people, and strict control of the construction period.

All aspects of project implementation process control

After each project is approved, comprehensive remote control from design, construction progress, safety, quality, etc., accurately control the total construction period of the site, follow up the progress of the project in real time, and make accurate decisions and solve any safety and quality problems in the first time.

Signing a contract

Technical Design

Civil works

Manufacturing

logistics transportation

Engineering installation

Debugging

Training

Turnkey Project

Lifetime Service

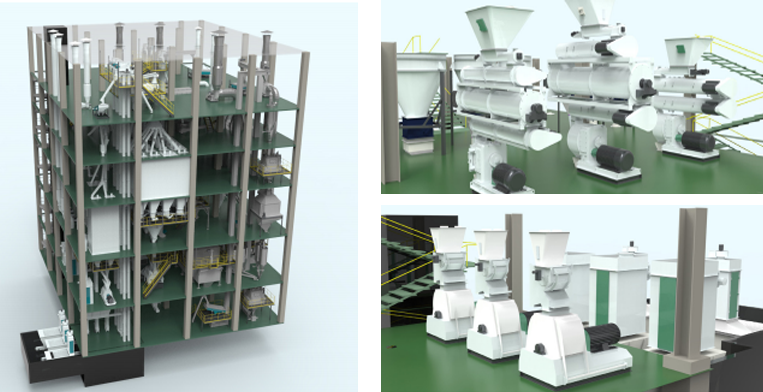

Three-dimensional design, standard prefabricated parts, engineering process control

Three-dimensional digital factory design, precise planning, one step in place!

Completely eliminate design errors! The use of international advanced design software, modular, parametric design, three-dimensional display model, in the design stage at a glance "with answers".

Automatically generate engineering drawings, work section drawings and non-standard prefabricated drawings to eliminate errors, ensure fine design, realize the whole process of equipment layout of the whole factory, and verify the rationality and correctness of the whole factory layout.

Prefabrication standardization reflects perfect engineering

86large categories,450A variety of prefabricated parts adopt three-dimensional standardized module design, which eliminates errors, is beautiful and elegant, reduces dead corners of materials in connection links, reduces residues, and is more convenient for operation and maintenance. Standardized production and on-site assembly of prefabricated parts in the factory greatly shorten the installation period and improve the engineering quality.

Feed engineering process control, so that the construction period quality problems have no place to hide

Zhengchang Feed Project Process Control257nodes, the progress of the project construction, safety, quality of comprehensive remote control, the total duration of the site construction is accurately controlled;

Company leaders can understand the progress of the project in real time, safety and quality in the first time to make accurate decisions to solve.

The progress of the project is based on real scenes to understand the installation situation of each site, and the safety, quality and degree of the project are controlled in an all-round way. If installation errors are found, the on-site head manager can be notified in time for rectification to ensure the timely and perfect delivery of each project. Horizontal comparison can also be made between the project departments of each project to automatically generate the progress achievement rate of each project, provide intuitive data for managers and adjust the on-site construction plan, and plan, promote progress, quality to achieve management objectives.

Delivery Management System

Project Quality Control

✦Comprehensive quality: project design quality, product manufacturing quality, engineering installation quality, commissioning service quality, staff work quality;

✦The quality of the whole process: throughout the whole process of design, production, manufacturing, installation, delivery and service, with the quality of work to ensure product quality;

✦The quality of full participation: full implementation of total quality management and ISO9001 management process, emphasizing prevention, adhere to quality standards, continuous improvement to enhance quality;

✦The quality of the whole company: the establishment of enterprise quality assurance system.

information needs

01

Contract Quality Review (Scheme)

02

Design Quality Review

03

Procurement and Manufacturing Management

04

Product packaging and shipping quality management

05

Quality control of engineering installation and commissioning

06

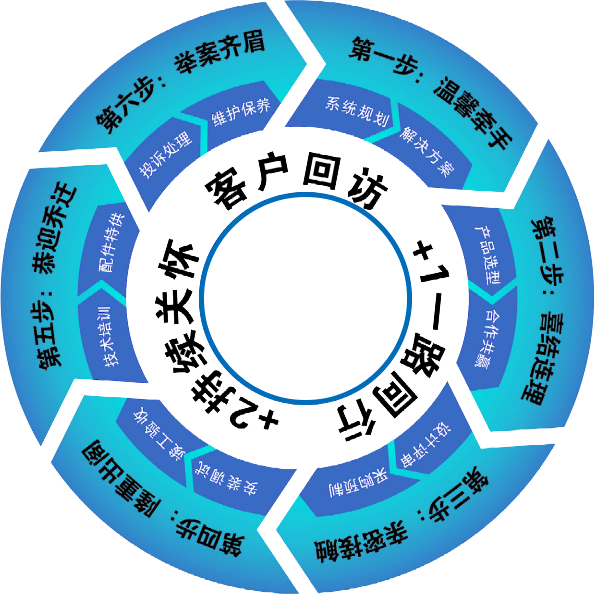

6+2 Perfect Service System

6+2/360 ° Perfect Service System

The introduction of global enterprise management software ERP system, including information management (CRM) system and sales (SD), procurement and finance (FI/C0), production planning (PP), quality management (0M) and other SAP systems that constitute enterprise production management. Standardize the management work, realize the seamless connection between the business of various departments, and make the rational allocation of resources: at the same time, it also standardizes the work flow between various departments and posts. Improve the work efficiency, reduce the cost of enterprises, improve the efficiency of product quality, can better provide services for customers.

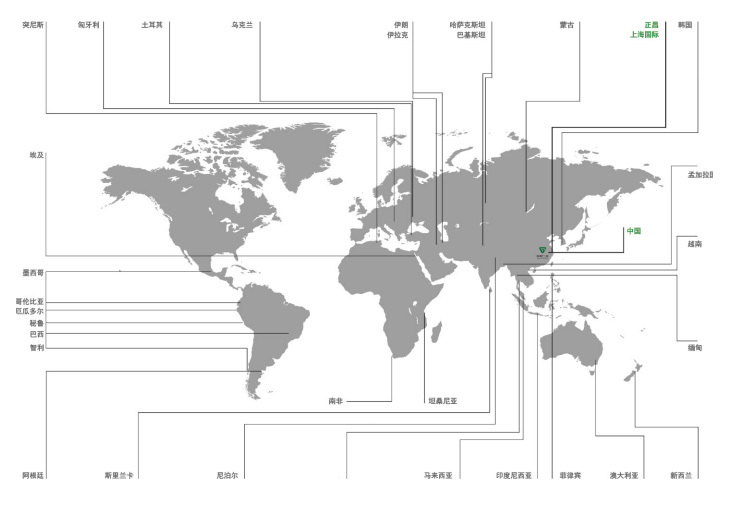

The global service network can provide you with technology, consultation and service support 24 hours a day, and can quickly appear in your side to help you solve the problems encountered in the process of using.

Global cooperation and win-win service

From the beginning of its establishment, it is determined to create the "extreme quality" concept of the whole industry and the whole system. Zhengchang products have introduced the concept of service from the beginning of design. The completion of each project is only the beginning of providing high-quality services for users.

Zhengchang has upgraded the traditional after-sales service in an all-round way, extending the service connotation to a series of links of product design, production, marketing and after-sales service. On the basis of the original 360 ° service system, it has carried out more than 50 upgrades to the entire service experience., Re-formulated the service method that is more in line with the actual situation and the service standard that pays more attention to user experience, launched the "6+2/360" omni-directional perfect service system.

Professional Accessories Service Company

① Zhengchang invested 80 million yuan to set up Jiangsu Zhengchang Granulator Technology Co., Ltd., a service-oriented enterprise specializing in the development and development of ring molds, pressure rollers and other molds, on the basis of the original Liyang Zhengchang Feed Machinery Parts Co., Ltd.

② With the core business of pelletizing machine R & D and manufacturing and related accessories services, we provide comprehensive and professional pelletizing service solutions for customers in the fields of feed, food, medicine, daily chemicals, biology and new energy.

Exhibition Of Key Projects

Shuanghui Group

Currently, the largest model of livestock and poultry feed production line in China.

Zhengda Kangdi Group

High-end pig feed production line + High-end livestock and poultry feed production line

Yisheng, Dongying, Shandong

Annual production line of 300,000 tons of high-end chicken feed

Jiangsu Haibo

Fish feed granule line + shrimp feed granule line + puffed line

Liaoning Haichen

High-end pet food production line

Jinhe Group

High-end forage production line

Model Works Presentation

Belarus Agricultural and Industrial Complex Project

China Grain Storage Lianyungang Direct Warehouse

Jindan Lactic Acid Storage Integration Project

Love Ju Kazakhstan Project

Phase II of the Jianghai Grain and Oil Transportation Project

Jiangsu Weiwe Food Co., Ltd. Insulation Warehouse Project