Agricultural machinery

Integrated Warehouse System

Spiral Warehouse

Assembly Warehouse

Insulation Chamber

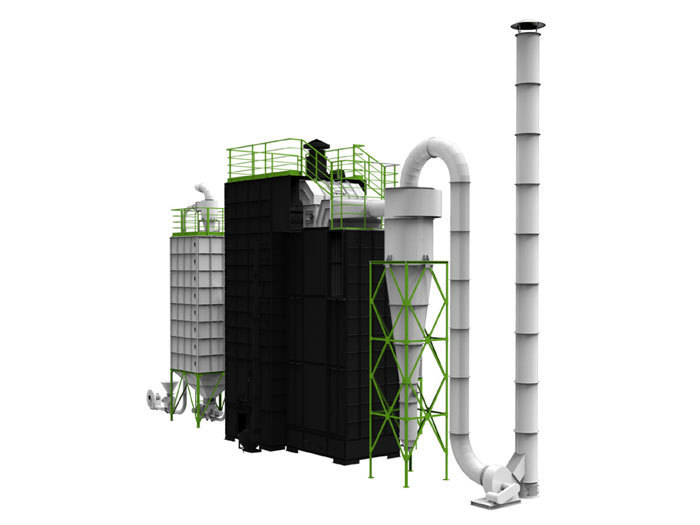

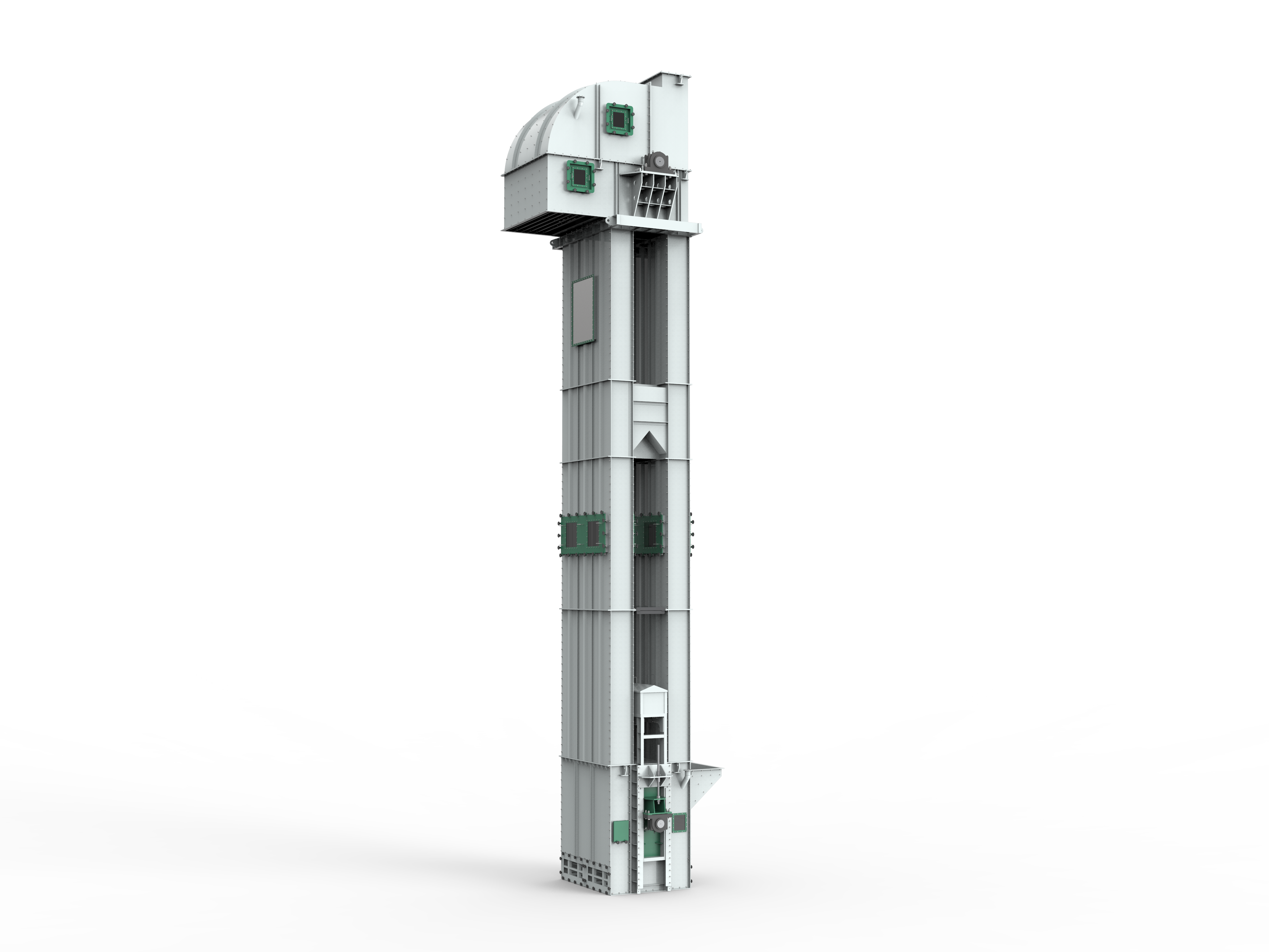

"Fengshen" Tower Dryer

"Fengchu" cyclic dryer

Heat source equipment

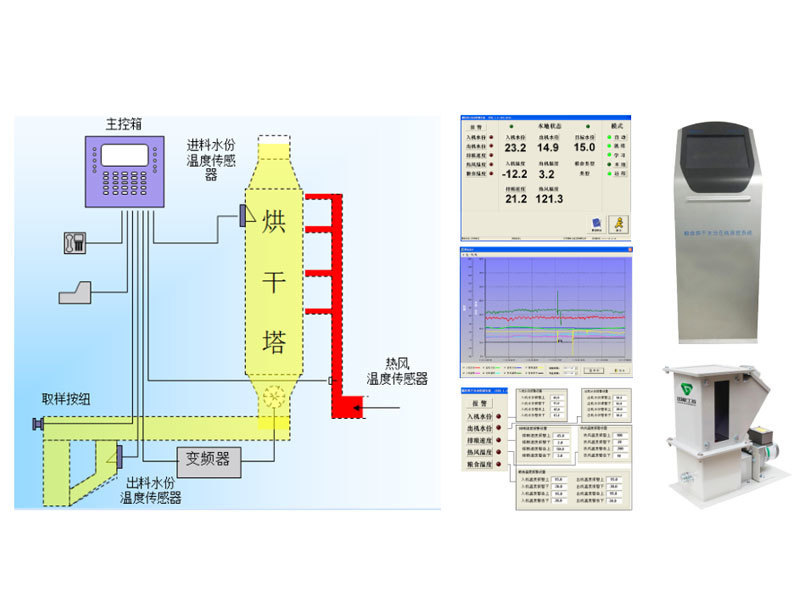

Online Measurement and Control System for Grain Drying Moisture

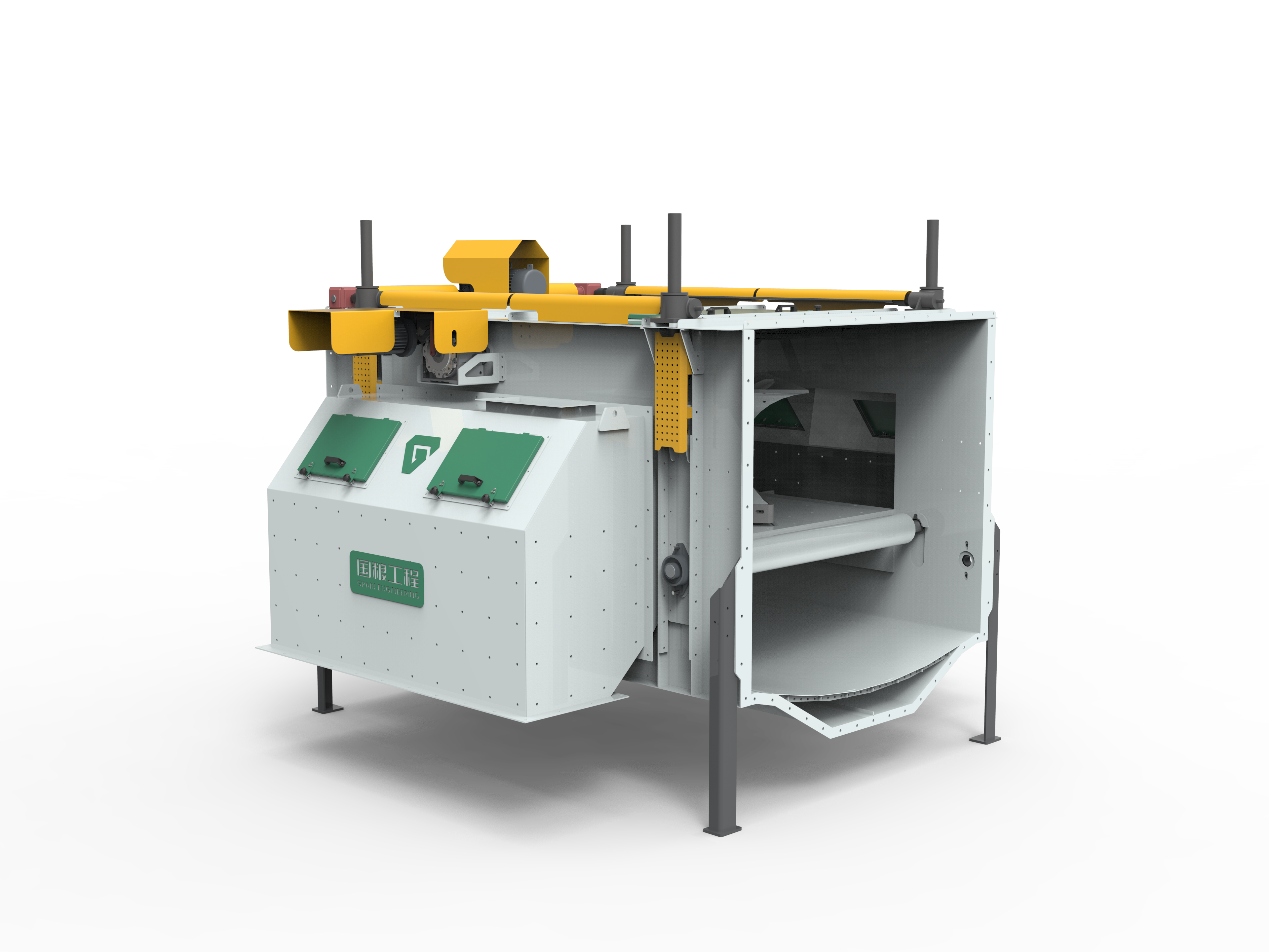

Air cushion plow-type unloader

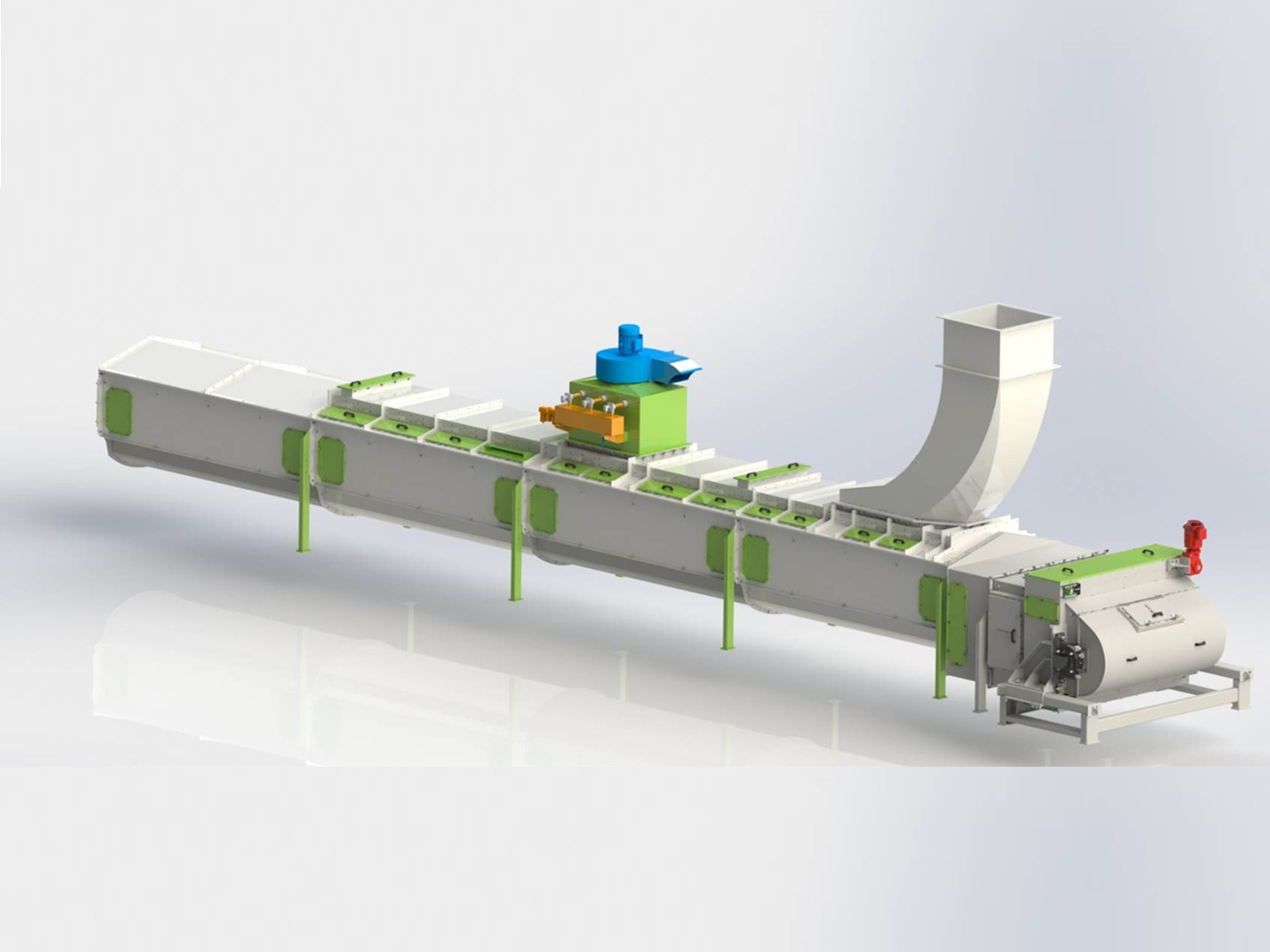

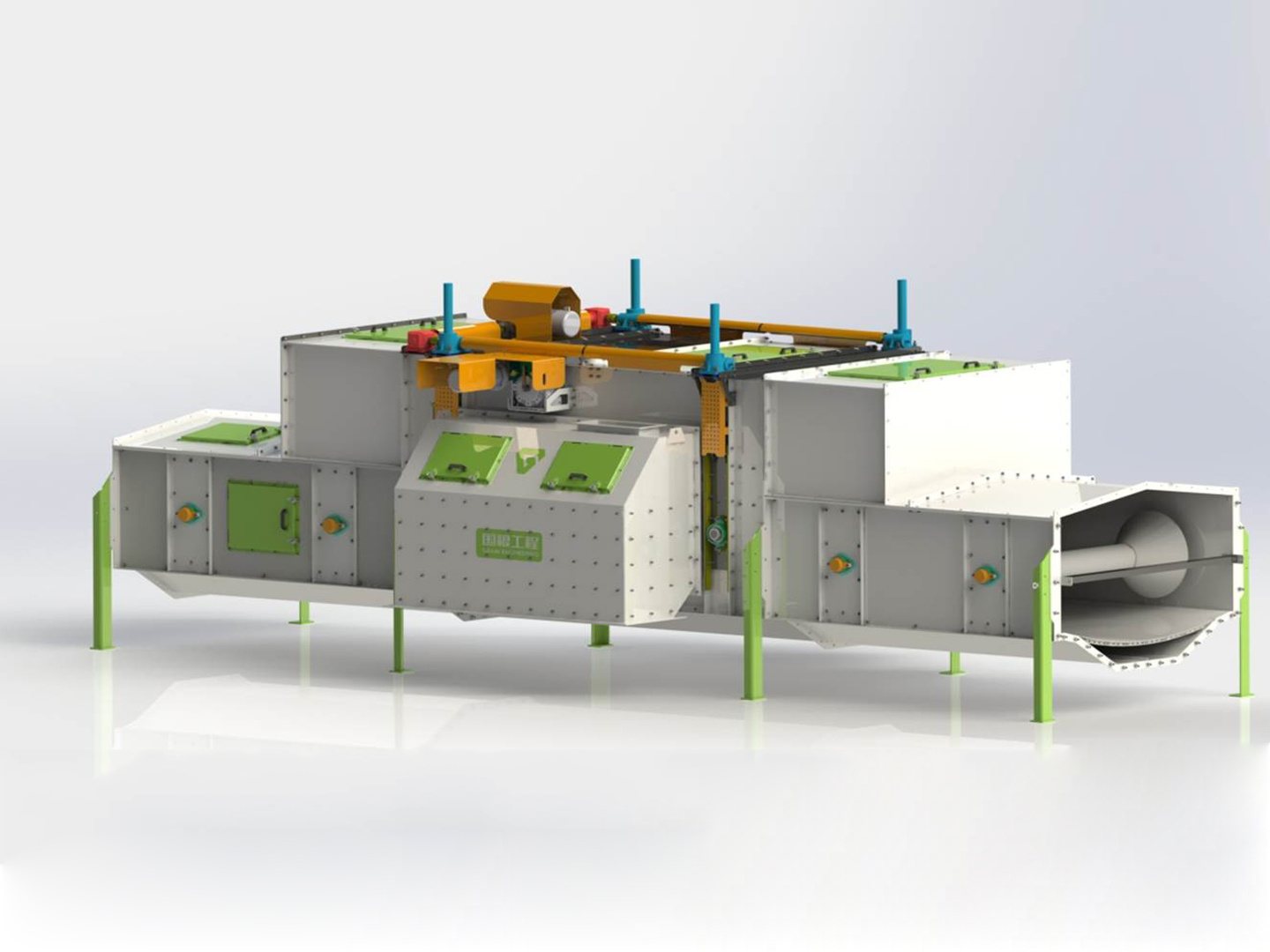

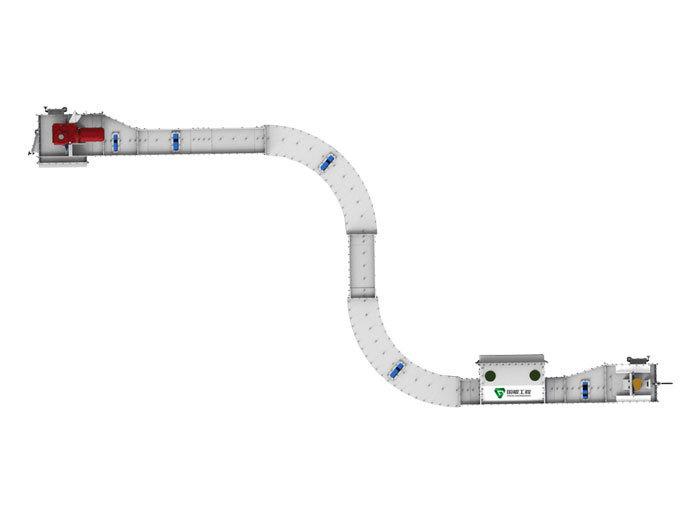

Air cushion conveyor micro-power dust-free transfer device

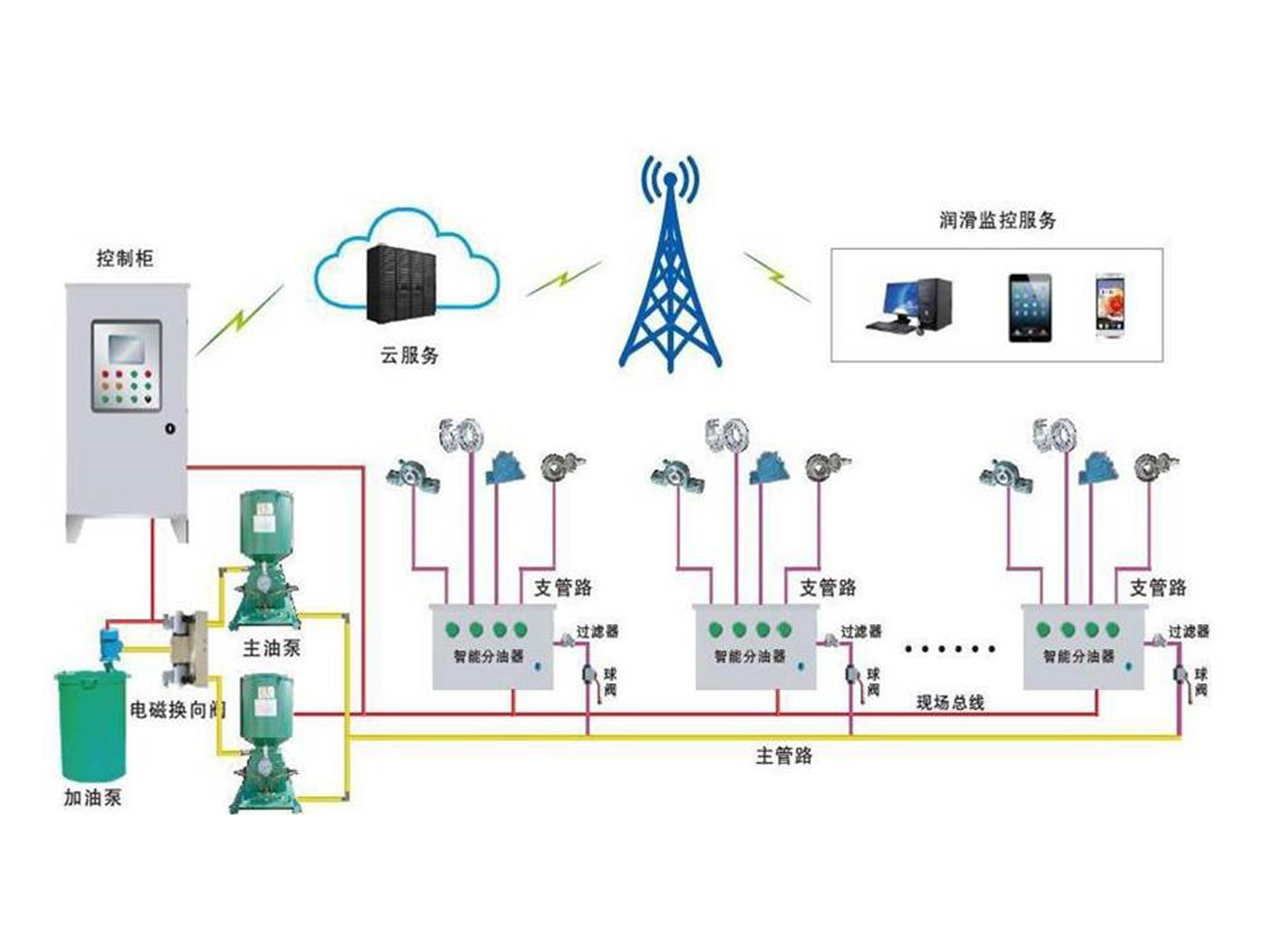

Intelligent Lubrication System

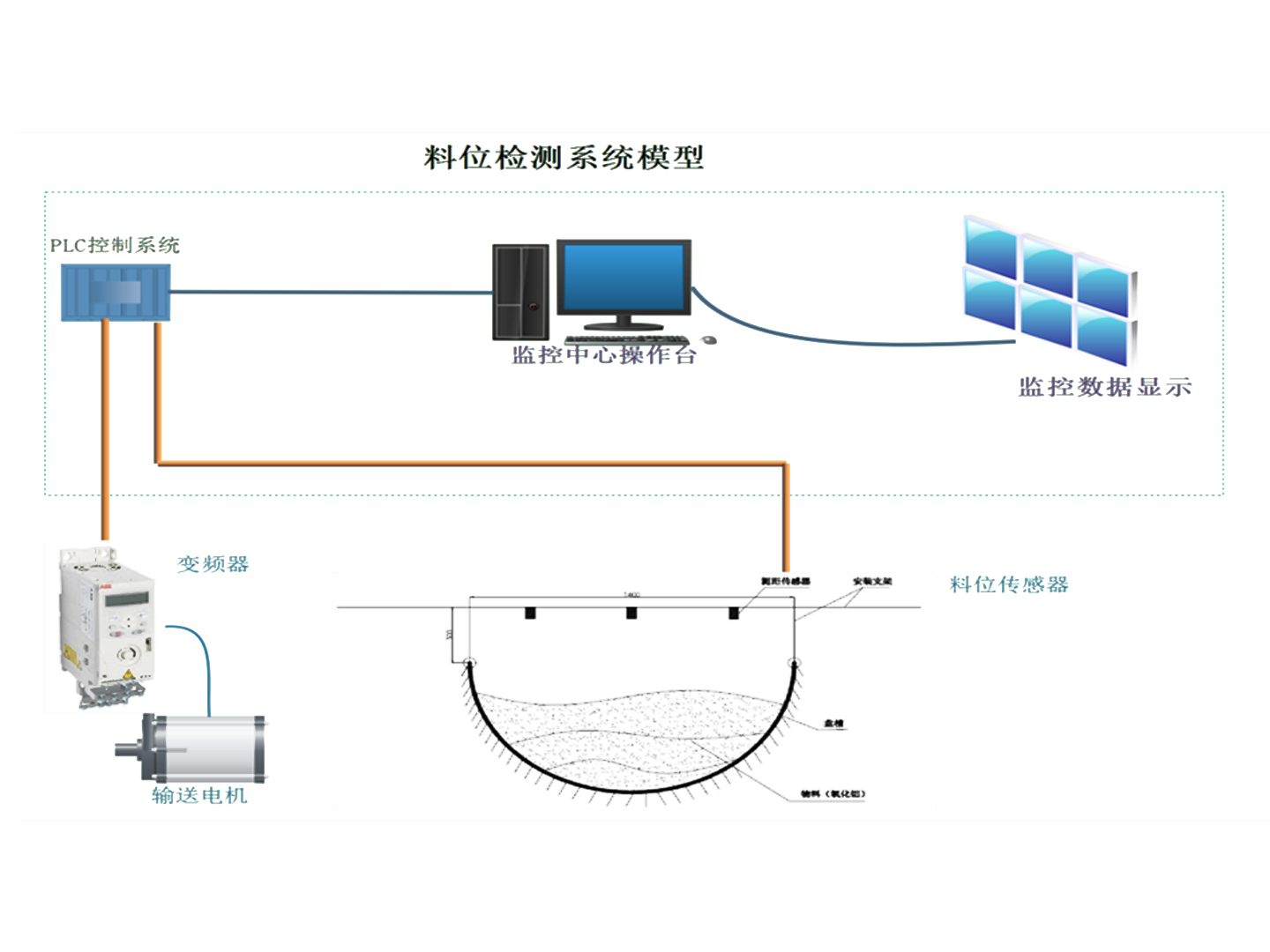

Intelligent Speed Control System

Single roller conveyor plow-type unloader

Small and Medium-Sized Conveying Equipment - TDTG Series Bucket Elevator

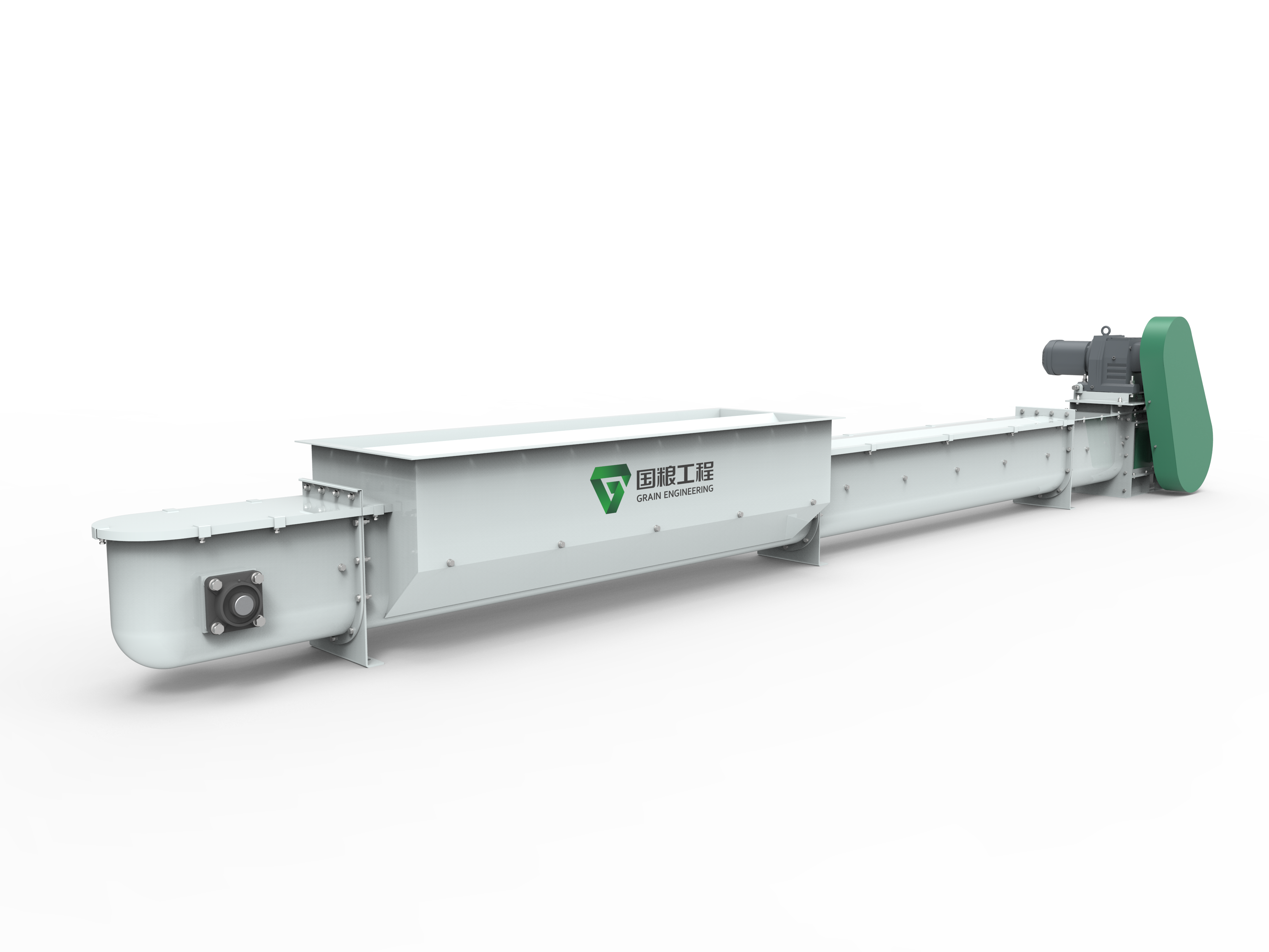

Medium and small conveying equipment - TGSU series self-cleaning scraper conveyor

Medium and small conveying equipment - TGSL series lifting scraper conveyor

Medium and small conveying equipment - TGSZ series lifting scraper conveyor

Large Conveying Equipment - TDTG Series Large Bucket Elevator

Learn More

Jiangsu Guoliang Storage Engineering Co., Ltd.

Jiangsu Guogang Storage Engineering Co., Ltd. is an enterprise specializing in grain storage engineering. It has the core technology of grain storage and grain protection in Zhengchang steel warehouse, and has absorbed the large-scale storage engineering technology company formed by the merger of Zhengchang conveying equipment and Zhengchang drying equipment. The company focuses on the design, development, production and manufacturing of complete sets of intelligent and green grain storage equipment, and is committed to providing customized and personalized storage integration and automation control solutions for global customers.