Feed Machinery

Focus on providing integrated solutions for global feed mills

Shuhua Material

Shuhua process can eliminate the anti-nutritional factors in raw materials, reduce the urease in soybean meal, suckling pigs do not pull thin, the survival rate is high. The medium-temperature shuhua + low-temperature granulation process retains the activity of functional substances in the raw materials and realizes the formula value of nutritionists. the suckling pig material produced is like "rice paste" instead of "popcorn" eaten by babies, which suckling pigs eat.not irritated, it grows fast. Can be selected after the spray fragrance process, color, aroma, taste, to further improve the feed intake of weaned suckling pigs. In the stage of teaching trough, the feed intake can be increased, and the total feed intake can reach 525~700g, which can improve the absorption capacity of the digestive tract of suckling pigs. Generally, the weight of suckling pigs will increase by 1kg when teaching trough, and the weight of large pigs will increase by 10kg.

Classic Case

![The Great Shepherd's factory produces 450,000 tons of high-end pig feed annually [Cases] The Great Shepherd's factory produces 450,000 tons of high-end pig feed annually [Cases]](https://omo-oss-image.thefastimg.com/portal-saas/pg2024083009002543561/cms/image/b10c4f21-23c5-4e21-8cca-b2e6bca66be3.jpg)

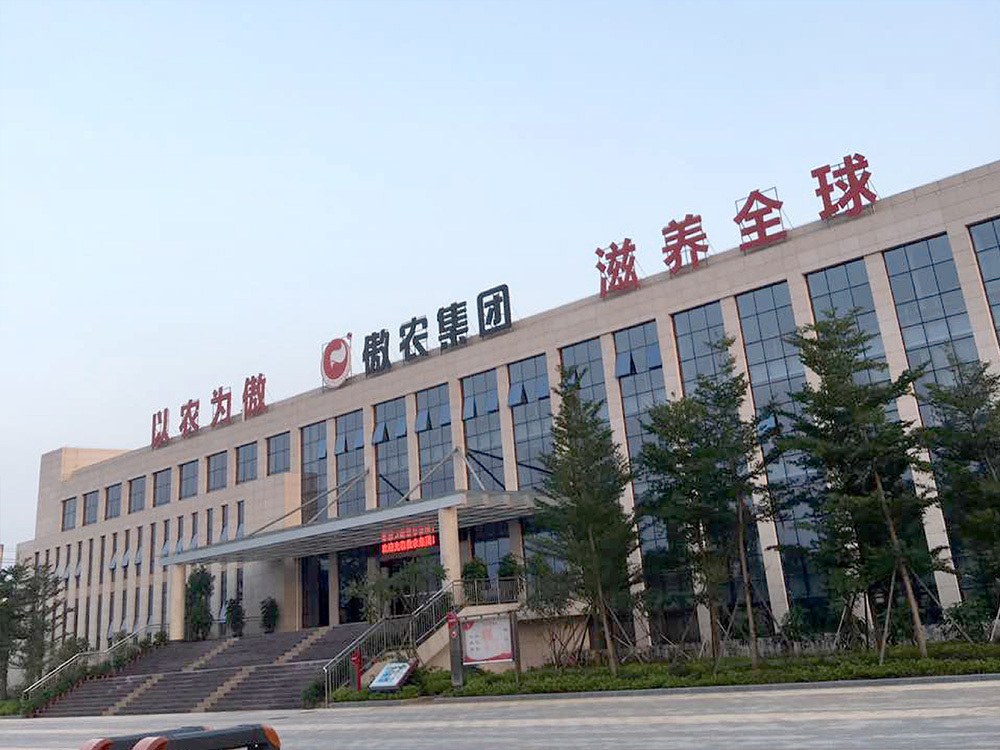

The Great Shepherd's factory produces 450,000 tons of high-end pig feed annually [Cases]

Good equipment, good craftsmanship, good feed. Da Muren collaborates with Zhengchang to build a high-end pig feed factory with an annual output of 450,000 tons, supporting the long-term development of the industry!

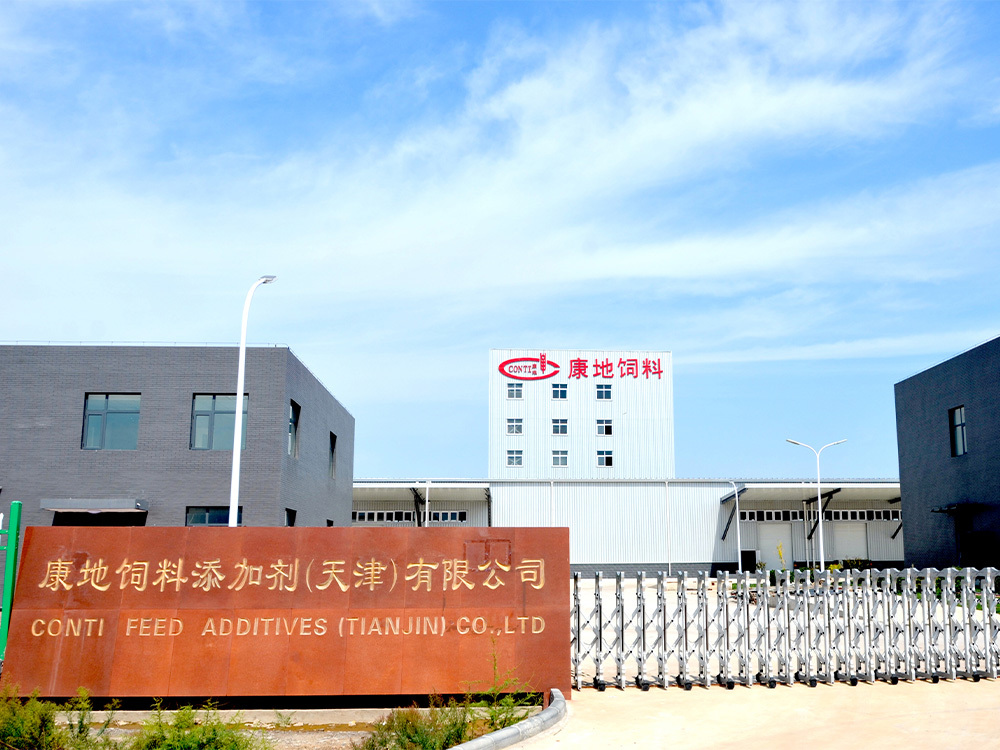

Tianjin Kangdi Feed Factory【Cases】

Kangdi Feed (Tianjin) Co., Ltd. is wholly owned by the American Kangdi Group. The project covers an area of about 53 acres, with an investment of nearly 100 million RMB. Its main projects include piglet feed production line, puffed production line, 508 granulation line, and premix feed production line, while also reserving production lines for ruminant feed and pet feed. All the feed production line projects mentioned above are exclusively constructed by Jiangsu Zhengchang Group.

Wuhan Kangdi【Cases】

Kangdi Feed (China) Group is a large agricultural industrial group established by the American Kangdi Grain Company in China. Its pig feed is the most expensive pig feed sold in China. In addition to the differentiation of the formula, the production process is also unique. The Wuhan Kangdi Feed Factory, built by Zhengchang Group, has now been fully put into production.

Hunan Zhenghong Feed

Pengshan New Hope

Yangjiang Chia Tai Pig Feed Production Line

Shandong Laibete 300,000 tons of comfort pig feed production line

A high-quality, efficient, and energy-saving feed production line tailored for the enterprise by Jiangsu Zhengchang Group. This production line consists of two 420 granulation lines and one 250 conditioning line, with all equipment, processes, technologies, and engineering provided and installed by Zhengchang Group, and it passed acceptance in one go in October. Currently, all three production lines are fully operational.

Little Rascal (Shandong) Biotechnology Co., Ltd. 【Cases】

Little Rascal (Shandong) Biotechnology Co., Ltd. is a manufacturing enterprise focused on the research and development and production of pet food, supplies, and raw materials. It is located in the Economic and Technological Development Zone of Linyi City, Shandong Province, covering an area of 150 acres, with a total investment of 812 million yuan. The first phase has completed construction on 50 acres, and the two production lines that have been built and put into operation can achieve an annual output of 30,000 tons of pet dry food, which has been listed as one of the top ten projects by the Linyi National Economic and Technological Development Zone.

Whole Process Customized Engineering Solution System

Zhengchang grain machine is a feed machinery industry as the main body of the feeding section machinery processing equipment and the whole plant engineering manufacturing enterprises. The company has established the goal of medium and long-term war road, standardized management of product design and development, procurement, manufacturing, sales and service process, so as to ensure that the whole product realization process is fully guaranteed, and the whole process forms a complete value chain. Each activity is a value-added process, creating value for customers, employees, suppliers and society.

From order requirements-technical design-planning-scheduling-material procurement-production execution-warehouse management-sales, shipment-commissioning and acceptance-after-sales service, the whole business flow management and control are realized, delivery tasks are completed on time, cost reduction and efficiency increase are realized, and customer satisfaction is improved.

Opening a Green Channel for Fast Delivery

In the face of projects with a short period of time, Zhengchang specially opens a green channel for you to shorten the installation period, I .e. to make various preparations before placing an order, such as detailed planning, project construction plan, all delivery batches, detailed completion of materials to people, and strict control of the construction period.

All aspects of project implementation process control

After each project is approved, comprehensive remote control from design, construction progress, safety, quality, etc., accurately control the total construction period of the site, follow up the progress of the project in real time, and make accurate decisions and solve any safety and quality problems in the first time.

Signing a contract

Technical Design

Civil works

Manufacturing

logistics transportation

Engineering installation

Debugging

Training

Turnkey Project

Lifetime Service

Learn More

Jiangsu Zhengchang Grain Machinery Co., Ltd.

It is one of the core enterprises directly under Jiangsu Zhengchang Group Co., Ltd. It is an enterprise integrating feed equipment and whole plant engineering, pet grain engineering and storage engineering. Its business covers more than 120 countries and regions in the world, providing more than 10000 sets of pelletizing equipment for 65% of Chinese feed enterprises, and constructing more than 8500 high-quality feed and storage projects for domestic and foreign customers.